Keep Ahead of Wear and Tear: Crucial Maintenance Tips for Undercarriage Parts

Wiki Article

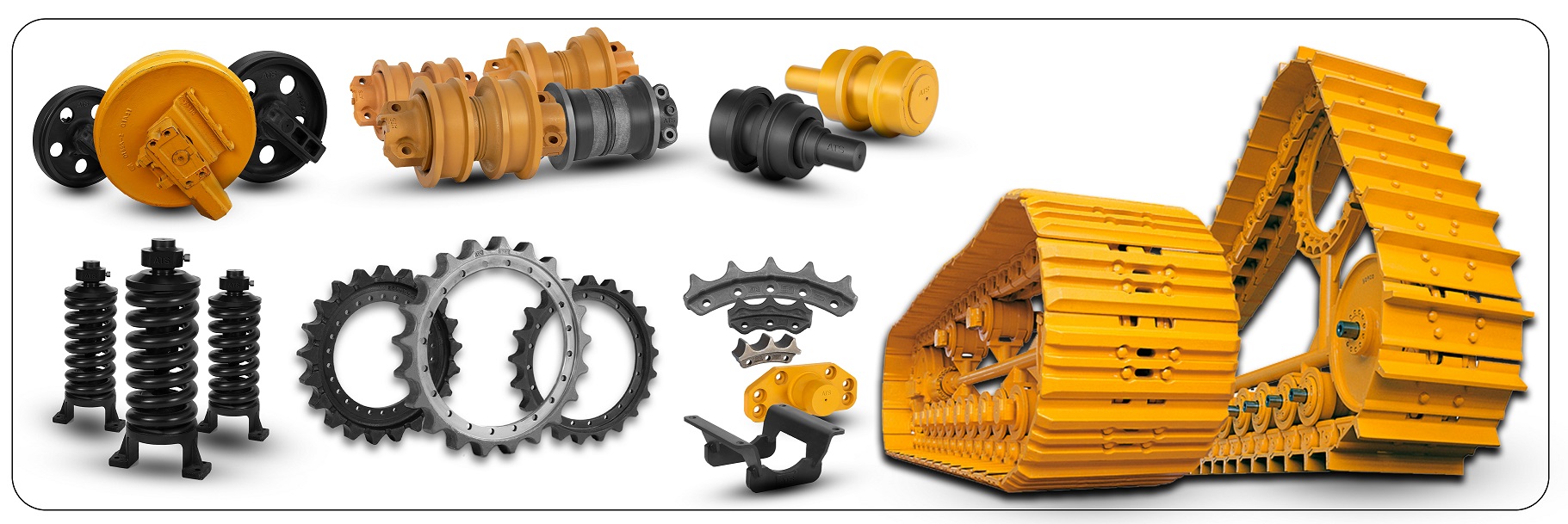

Make Best Use Of Performance With Sturdy Undercarriage Components

In the realm of heavy machinery and equipment, the role of undercarriage parts is paramount in guaranteeing ideal performance and longevity. The performance and effectiveness of these components can dramatically affect the overall operation of equipment, making the selection of sturdy undercarriage components a vital choice for supervisors and drivers alike.Benefits of Using Resilient Undercarriage Components

Using resilient undercarriage components not just improves the durability of hefty equipment but also minimizes upkeep expenses significantly. By investing in premium undercarriage elements, such as tracks, rollers, gears, and idlers, tools drivers can experience increased uptime and enhanced general efficiency.

Additionally, the durability of heavy machinery is straight linked to the high quality of its undercarriage parts. Resilient parts can stand up to the roughness of demanding applications, making sure that the devices remains operational for extensive durations. Because of this, drivers can stay clear of costly downtime and upkeep expenses, inevitably optimizing the roi for their equipment.

Factors Affecting Undercarriage Resilience

The sturdiness of undercarriage parts in hefty equipment is affected by numerous important factors that directly influence performance and long life. Top quality products, such as hardened steel, are essential for withstanding the extreme problems and hefty lots that undercarriage parts are subjected to - undercarriage parts.Additionally, environmental variables can have a significant impact on the durability of undercarriage components. Direct exposure to rough products, extreme temperatures, and severe working conditions can speed up wear and tear on undercarriage elements. Choosing undercarriage parts that are particularly designed to withstand these ecological challenges is crucial for making sure durability.

Additionally, the design and design of undercarriage components have a straight impact on their longevity. Parts that are created to distribute lots equally, minimize friction, and minimize tension focus are more likely to have a longer life expectancy - undercarriage parts. By considering these crucial elements, equipment drivers can make best use of the sturdiness and performance of their undercarriage elements

Maintenance Tips for Lengthening Undercarriage Life

Executing normal maintenance routines is crucial for expanding the lifespan of undercarriage parts in heavy equipment. To extend the undercarriage life, it is critical to frequently check for damage. Routinely look for missing or loosened bolts, damaged rollers, or misaligned tracks, as these issues can rise and cause additional damages if not addressed immediately. Furthermore, make sure that the undercarriage is appropriately lubricated according to manufacturer guidelines to minimize friction and avoid early wear.An additional vital maintenance suggestion is to maintain the undercarriage clean from dirt, rocks, and debris. Build-up in the undercarriage can increase wear and corrosion, leading to pricey repairs. Washing the undercarriage after procedure in extreme problems is advised to avoid these concerns.

Lastly, tracking and recording upkeep tasks can help in developing a positive upkeep routine. Keeping thorough records of fixings, substitutes, and evaluations can supply valuable insights right into the undercarriage's condition and efficiency in time, helping in forecasting and preventing potential failures. By following these upkeep tips faithfully, drivers can significantly raise the resilience and performance of undercarriage parts in hefty equipment.

Selecting the Right Undercarriage Components

Selecting appropriate undercarriage components is vital for maximizing the efficiency and longevity of heavy equipment. When it comes to selecting the appropriate undercarriage components, there are several factors to think about.Opting for credible brands recognized for generating sturdy and high-performance undercarriage parts can click here for more substantially affect the total performance and longevity of the machinery. By very carefully choosing the right undercarriage elements, equipment owners can boost this hyperlink productivity, reduce downtime, and extend the life-span of their heavy equipment.

Instance Researches: Boosted Performance With Long Lasting Parts

Including long lasting undercarriage parts has demonstrated considerable improvements in equipment efficiency. One case study involved a building and construction business that updated its excavator's undercarriage elements to much more resilient options. The business observed a significant decline in downtime due to undercarriage maintenance, resulting in enhanced productivity and price financial savings. The long lasting components endured extreme working problems, reducing wear and tear dramatically.In one more instance, a mining procedure changed the undercarriage components of its bulldozer with premium, long lasting options. This button resulted in a remarkable enhancement in the bulldozer's ability to move and general performance. The maker could browse tough surfaces extra effectively, resulting in improved functional effectiveness and lowered gas intake.

Additionally, a logging firm purchased long lasting undercarriage parts for its forestry devices. The upgraded parts showed prolonged life expectancy and increased resistance to abrasion from harsh surface. The company experienced decreased upkeep prices and improved devices uptime, eventually increasing its bottom line. These study highlight the tangible benefits of making use of sturdy undercarriage parts in maximizing equipment performance and durability.

Conclusion

In final thought, making use of resilient undercarriage parts can substantially enhance efficiency and durability of hefty equipment. Situation researches have actually shown that spending in sturdy undercarriage components can lead to boosted overall efficiency and performance in numerous industries.The effectiveness and effectiveness of these parts can considerably influence the general procedure of machinery, YOURURL.com making the choice of resilient undercarriage parts a vital decision for supervisors and drivers alike.Incorporating sturdy undercarriage parts has actually shown substantial improvements in machinery performance. These case research studies highlight the tangible benefits of using durable undercarriage components in enhancing equipment efficiency and longevity.

In verdict, making use of resilient undercarriage parts can considerably enhance efficiency and durability of heavy machinery (undercarriage parts). Case researches have revealed that spending in resilient undercarriage components can lead to enhanced overall performance and performance in numerous markets

Report this wiki page